Double Drum Winch and Spud Setup

- Position the spud pockets on opposite sides of the barge deck.

- The contractor must supply the 5/8″ cable. A minimum of one layer of cable should be on the winch spool during use.

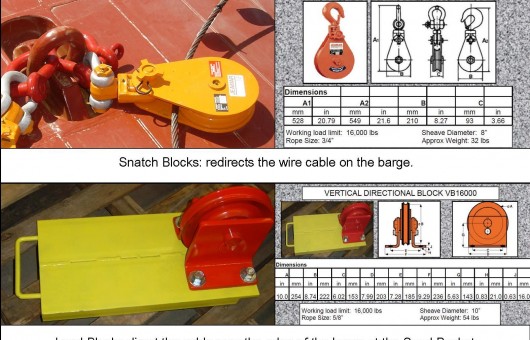

- Tack weld the vertical lead block assembly in front of the spud pocket. The vertical lead block directs the cable over the edge of the barge in-between the spud and the barge.

- Carefully wind the cable onto the first drum until it covers the entire drum, then run the cable to the opposite spud.

- Direct the cable over the verical lead block, down to the bottom of the spud, through the sheave and then back up the other side. Clamp the line off on the spud pocket using cable clamps.

- Do the same with the second drum, direct the line through the snatch block, clipped to the top of the connector pin, then return the cable to the spud behind the winch.

- Follow the same steps outlined in step 5.

- Both Spuds can be raised and lowered with the winch.