Pautas de uso general

Un mínimo 100 Se requiere grúa para cargar toneladas frente a las barcazas desde el camión al agua. Each barge has a single lifting clevis or shackle in the top of the barge for easy loading and unloading. Poseidon® 1 -10’ x 40’ x 5’ barges weigh 23,500 libras. Poseidon® 2 -10’ x 40’ x 5’ Sectional Barges weigh 23,700 libras. each and Poseidon® 3 Barges weigh 23,700 libras. each. Tag lines should be attached to the ends of the barges to control the movement of the equipment while in the air. After pulling the barges together, have a couple of men stand on the outside of the barges in order to cause the barge to come together at the bottom. An alternate method is to thread a small choker through the rope thimbles on both barges and lift up slightly with the crane. Once the bottom is together, carefully drop the 55 lb. pin in place being careful not to pinch your fingers.

The Poseidon® 1

barge has a Rendrag® compatible connection system. Hairpin connectors are dropped into position. The 40’ x 10’ x 5’ barges are equipped with 8 connection points on the sides and 2 connection points on the end. Each 40’ x 10’ x 5’ barge can support 35,000 lbs at a 2’6” draft. Rope thimbles on the sides and ends of the barges are used to assist in pulling the barges together prior to pinning.

The Poseidon® 2

barge has a Flexifloat® compatible connection system. The internal locking clasp is pried up with a lifting bar. The barges are pulled together using ropes in the rope thimbles. An alternative method would be to run a small choker through both rope thimbles and lift up slightly with the crane. This will draw the bottom of the barges together. The barges need to be near touching before the locking bar will drop down at the top or the bottom. The locking clasp may be tapped into the locked position with a small hammer.

The Poseidon® 3

barge is Shugart® compatible. The P3 barge has a set of upper and lower angles on the sides and ends of the barge. There are 32 pin holes on the 41’4″ length and 8 pin holes on the 10’4″ end. The P3 barges must be assembled so that the narrow side angles fit above and below the wider side angles on he opposing barge. Line up and secure the pin on the end of the barge, then fold the barge together against the opposing barge, drop the pins into the angles beginning at the opposite end.

Use of Hardwood Mats on Poseidon Barges

The contractor must supply and use oak or yellow pine 8" - 12" crane mats when using cranes, excavators or any other pieces of equipment with steel crawler tracks or rubber tire equipment. Below are examples of damage that has occured to barges when they are not used properly. The sides, ends& bottom skin surface of the barge is made of A-36 1/4” steel plating. The tops are covered with a skid resistant 11 gauge patented roll form material. Damage to the barges on the project will be repaired and invoiced back to the contractor. Pictures of the damages will be taken along with an estimate of the repairs prior to the work being completed for the contractor’s review. Below is a sampling of pictures from damaged equipment returned after the project.

DAMAGE:

Any defect that structurally impairs or degrades the equipment in its ability to perform the intended function and duty including, but not limited to, providing flotation for construction equipment. Or, any defect that materially degrades the commercial resale value of the equipment, beyond an amount typically expected based upon the duration, duty cycle, and type of work performed during the rental period.

Specific Damage Criteria for Equipment Sides, Ends, Decks, or Bottoms:

- Any structural member deformed by ¼” or greater. (Angle, channel, formed pocket, casting, rope thimble)

- Any plate section deformed by ½” or greater, regardless of size of defect

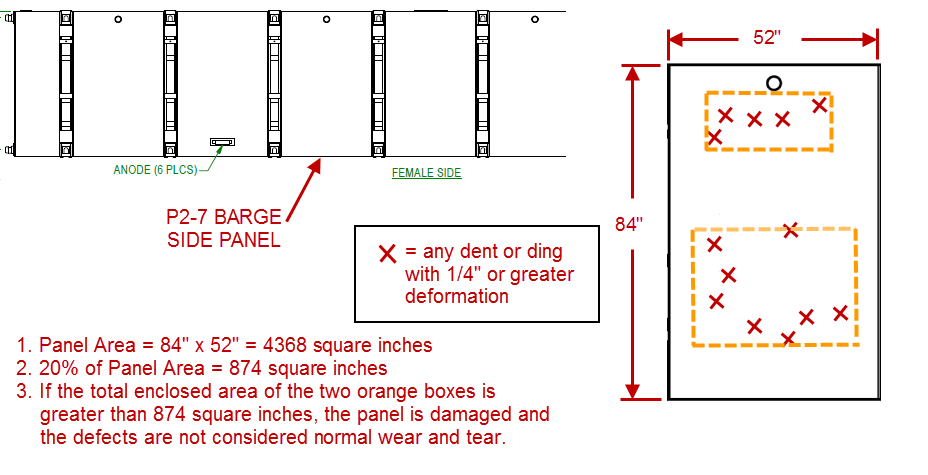

- Any plate section deformed by ¼” or greater when defect distribution is 20% o más de área cuadrada del panel. (Consulte la imagen siguiente).

- Cualquier agujero o desgarro donde se perfora se considera daño material de acero.

Ejemplo DAÑO Evaluación del CÁLCULO: 20% REGLA PANEL DE ÁREA

Fotografías e ilustraciones DE DAÑO EJEMPLO

Laminado de tapas o de lavado de embarque se produce como resultado de no usar las esteras de madera. esquinas dañadas y paneles de extremo se produjeron cuando los lados y extremos de la barcaza se vieron afectados con una cuchara de excavadora o con las rodillas de empuje del barco remolcador. las tapas, lados y extremos de estas barcazas fueron reemplazados y costos fueron trasladados al contratista. La placa exterior se corta y se retira junto con ángulos dañadas interiores y la estructura. Las piezas de repuesto se sueldan en su lugar, recubierto con inhibidor de óxido bio-flotador en el interior y el exterior es golpeado y se pinta con una imprimación de uretano Baril rico en zinc y un bajo brillo acabado alifáticos poliuria.Tan pronto como su operador golpea el lado de la barcaza con la cuchara de la excavadora o una roca o de otros desechos pesados cae sobre la cubierta de la barcaza causando mella, parar inmediatamente, tomar fotografías de los daños, documentar la fecha y la hora en que ocurrió el incidente e informar de los daños a su compañía de seguros. Debe proporcionar una fecha específica oocurrencia f para el proveedor de seguros a fin de que el daño sea cubierto.El operador debe ser entrenado en el uso adecuado de los equipos con el fin de no repetir el daño de nuevo. También notificaPoseidon® Barcaza de los daños.

El contratista puede soldar hierro en ángulo adicional, abrazaderas, etc.. para asegurar cualquier equipo en las barcazas.Poseidon® Barge requiere que estos elementos pueden quitar y fragmentos restantes molieron hasta la superficie original antes de devolver la barcaza al final del período de alquiler. La pintura de aerosol del área de terreno con Red / Brown Oleum Pintura.

Spuds and pockets are available to secure the barge in position on the water.Spuds should be supported by two chokers or nylon straps rated to lift 10,000 pounds or more prior to the truck driver removing the chains or straps securing the spuds to the truck bed. Esto asegurará que no ruedan o se deslizan fuera de la camioneta expectante. Spuds se bajan a la superficie de fondo del lago, estanque o río y empujado en el barro debajo. The barges can also by tied off by rope or cable through the thimbles on the sides or ends of the barges or by using the cleats supplied by Poseidon® Barge.

Do not pound on the top of the spud with an excavator bucketas this will damage the spud. Repairs to the spud due to such activity will be charged back to the contractor. Spuds can be raised and lowered by a crane line or by a hydraulic winch. Poseidon® Barge offers double drum winch units for sale or for rent. 5/8” Steel cable is tied off on the outside of the spud pocket on the lifting eye, threaded through the 20” sheave at the bottom of the spud and then brought up through the spud pocket and attached to the winch. If you run steel cable from the barge or winch across the body of water you are working on to the shore, bright orange vinyl ribbons should be hung from the cable, making it visible to any water craft that is operating in the vicinity.

Rental Rates do not include insurance on the barges. A Certificate of Insurance naming Poseidon Barge, Ltd as “Additional Insured” under your general liability policy, plus listing us as a “Loss Payee” under your equipment floater policy for dual protection against physical damage must be supplied, prior to shipping the barges to your job site. Additional details and requirements are included with our quote and lease agreement.

Adequate trainingfor operating the equipment, transported and used on the barges is the contractor’s responsibility. Poseidon® Barge, Ltd are not liable for any accidents due to operation of equipment on the barges under any circumstances including unsafe weather conditions, such as high winds, thunder storms, heavy rains, high wake, and icy or heavy snow conditions or any other hazardous weather conditions. Normal loading, unloading, dredging processes, and high humidity in the air may cause water to pool on all working surfaces on the barges. Care must be taken by equipment operators and workers to ensure the safety of the workers and equipment. Life vests should be worn at all times when working around the water. In sub-freezing air temperatures, ice will form on the barges and crane mats. It is the contractors responsibility to take any and all precautions in safe guarding their employees as well as the general public.

Minimum width necessary to float equipment.Poseidon® does not recommend floating a 25-30 ton excavator on a platform less than 30′ wide (3 sections 40′ x 10′ x 5′ wide). Adicionalmente, if you are performing dredging work in hard digging conditions, Poseidon® also recommends a minimum of 4 spuds and pockets to minimize possible damage to the spuds & pockets as a result of the pulling energy caused by the bucket in hard soil conditions. If the contractor observes that Poseidon® equipment is getting dented up, spud pockets are being pulled apart, and or spuds are getting bent as a result of the excavator being too large for the platform, soil conditions are too hard or the operator is using the equipment in a careless manner, it is the contractors responsibility to change the parameters of the project and find an alternative method to complete the project. The contractor is responsible for all damages to the equipment. Just because our barges will float your equipment does not mean they can withstand the additional abuse as a result of difficult & hard digging conditions.

Poseidon® Barge offers static stability analysis for the use of floating cranes. Our analysis is only as good as the information provided. Knowing the make and model of the crane, la longitud de la pluma, el radio va a trabajar con la grúa, el peso pico y el peso y el tipo de equipo adicional que va a flotar en la barcaza ayudará a nuestro personal para hacer las recomendaciones adecuadas.

Antes de devolver el equipo, Todo el crecimiento marino y la suciedad deben limpiarse de las barcazas.crecimiento marino incluye percebes, briozoos, moluscos, poliqueto y otros gusanos de tubo, mejillones cebra, algas marinas, algas & cualquier otra suciedad o limo en la superficie barcaza. Es posible que deba raspar las barcazas y limpiarlas con vapor después para matar cualquier material restante en la barcaza. SiPoseidon® tiene que volver a limpiar el equipo, los gastos de limpieza serán facturados volver al contratista.

Toda el agua de lastre y el agua acumulada debido a la condensación se deben retirar de las barcazas antes de sacarlas del agua y cargarlas en el camión.El agua dentro de la barcaza hará que la carga tenga sobrepeso.. La barcaza no se elevará uniformemente fuera del agua ya que hay un solo punto de elevación en el centro superior de la barcaza.. También, el cambio de agua dentro de la barcaza puede hacer que la barcaza se mueva en el camión si el conductor tiene que detenerse rápidamente. El agua se puede expulsar con un compresor de aire y los tapones de lastre de agua en las esquinas superiores de la barcaza.. It can also be pumped out or if necessary, cut a 2” hole on the sides of the barge towards the end approximately 3” from the bottom to drain the water out prior to shipping. Please notify us when doing this, so that we can anticipate the repairs. The Poseidon® Barge system is designed for easy handling and economical transportation to and from your project.

Poseidon® Double Drum Winch: Daily maintenance and inspections should be done to assure safe operation. Oil levels should be checked daily. The key is located on the dip stick when you first receive the unit. The engine should be started and allowed to idle for a minimum 30 minutes to allow the hydraulic oil to heat up. Operating hydraulic equipment with cold hydraulic oil could cause seals to break resulting in hydraulic oil spills. We use 46 weight Clarity Oil in our equipment to minimize environmental impact. Wire cable is not supplied by Poseidon® with the winch. All cable is to be removed prior to returning the winch and the fuel tank should be filled up. Tape the wedges to the drums using duct tape.

Poseidon Sea Bees: mantenimiento e inspección diaria se debe hacer para garantizar un funcionamiento seguro. Los niveles de aceite deben ser actualizados diariamente. Las unidades deben iniciarse y se dejan en reposo durante un mínimo de 30 a 90 minutos para permitir que el aceite hidráulico se caliente dependiendo de la temperatura del aire. Los niveles de aceite deben ser revisados en una base diaria. Las mangueras deben ser comprobar visualmente para asegurar que no haya pliegues o fugas en las mangueras. Si se golpea la hélice en una roca o un árbol, detener la unidad inmediatamente e inspeccionar la hélice de cualquier daño. Esto puede causar que el sello en el motor hidráulico en el alojamiento prop para romper o doblar el eje de la hélice. Si se produce este, the 8″ steel tube shaft will fill up with hydraulic oil. If you notice oil leaking out of the top of the steel shaft, shut down the unit immediately and call Poseidon® to make arrangements for a repair.

Winch Units & Barge Pusher Units should be secured with four long chokersunido a los soportes en los marcos de las unidades y sostenido por la línea de la grúa antes de que el conductor del camión retire las cadenas o correas que sujetan las unidades al camión. Esto asegurará que las unidades no se muevan o se caigan del camión causando expectación daños en el equipo o lesiones al personal de tierra. Las unidades deben permanecer nivel a medida que se despegaron de la camioneta.